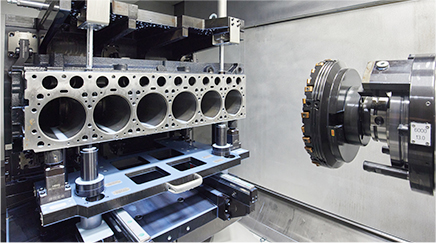

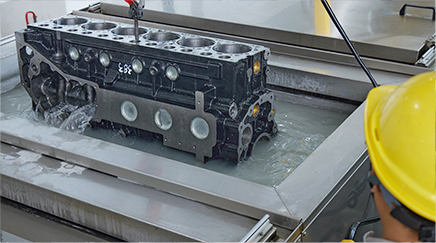

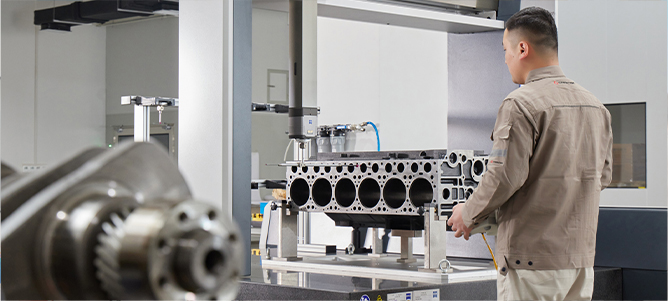

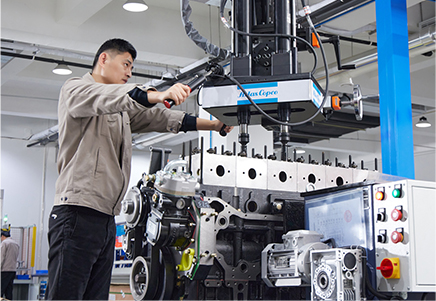

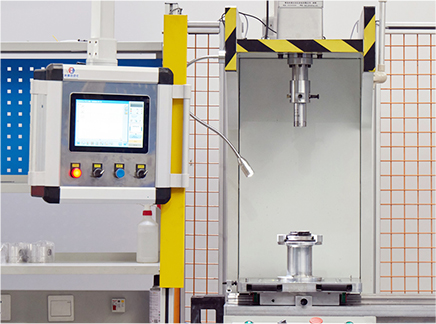

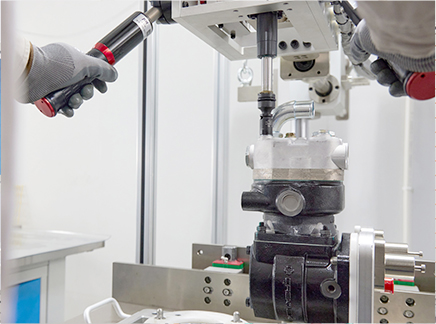

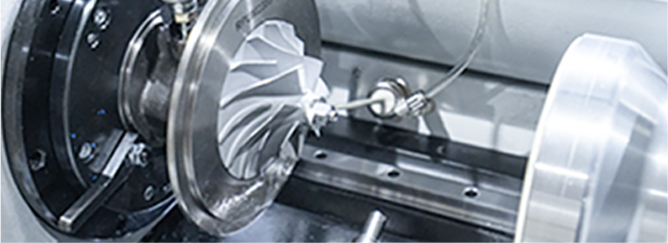

CREATEK Machining Center has dozens of senior engineers, and is equipped with cutting-edge production machines such as Heckert HEC800 horizontal machining center imported from Germany and high-precision CNC honing machine. Here, small-batch and multi-assortment flexible machining can be carried out for parts like engine cylinder blocks, cylinder covers, and air compressor cylinder blocks to meet customers’ diversified production demands. By controlling the key processes of parts, the product consistency is ensured to meet customers’ high-quality production demands.